The key difference between LEDs and other lamps, whether they are incandescent bulbs or compact fluorescent lamps, is that they are much more energy efficient. LED’s use 1/10th the energy of the older light bulbs, and about half the power that goes into CFLs, to emit the same amount of light. The problem, however, was that LEDs had a much higher initial cost, making the payback period too long to be economically viable.

In 2012, a report by the Electric Lamp & Component Manufacturers’ Association of India claimed that limited availability of technology as well as the lack of incentives from the government was stunting LED growth in the country. At the same time, both manufacturing capacity and output of CFLs have been growing massively.

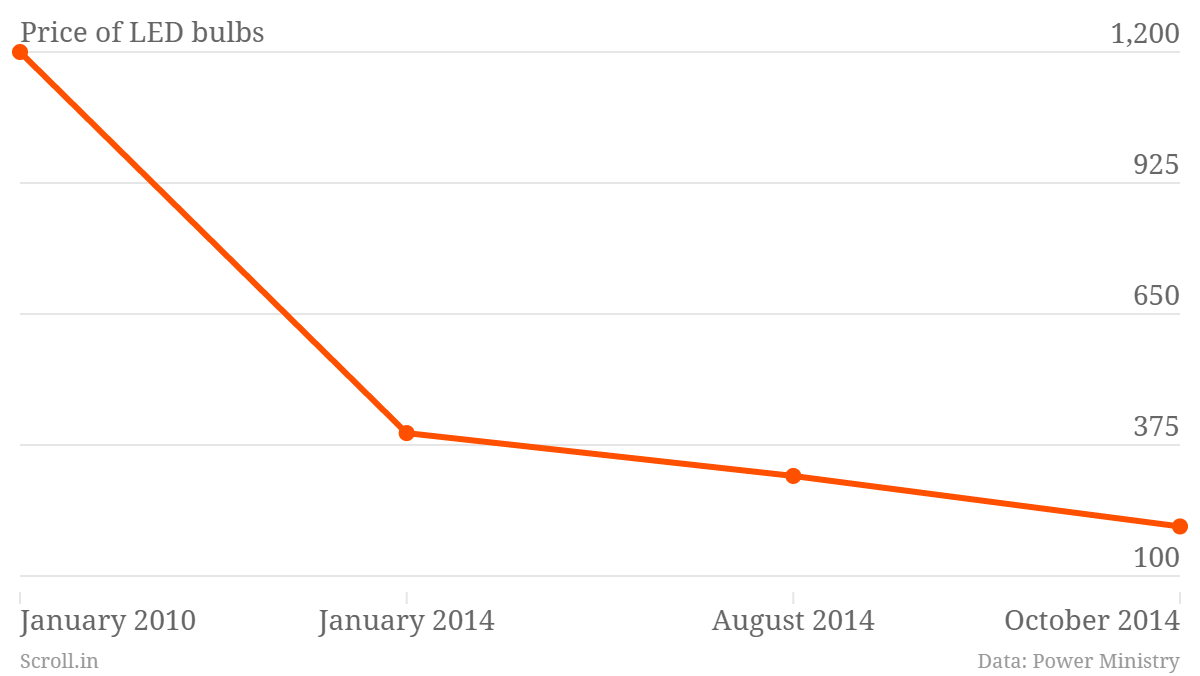

According to India’s power ministry, the first LED lamp that was made in India was sold for Rs 1,200 in 2010. This was far too expensive for it to be widely used, so the Bureau of Energy Efficiency and the power ministry decided to work on actively spreading the technology.

“BEE simultaneously promoted demand for LED bulbs and for LED streetlights by providing financial support to all states to set up demonstration projects to highlight the lighting quality and energy savings of this technology,” said the power ministry.

Subsidising light

Additionally, LEDs were integrated with the Rajiv Gandhi Grameen Vidythikaran Yojana, which aims at creating rural electricity infrastructure. The power ministry decided that all the bulbs being provided to below-poverty households would use LED technology.

The BEE then started a project to alter the LED business model in such a way that the technology would become both affordable and add plenty of savings. Energy Efficiency Services Limited, a joint venture of four power Public Sector Units, was tasked with procuring LED bulbs in bulk and selling them to households at Rs 10, rather than the market price at the time, which was Rs 400.

If this happens on a large enough scale, electricity distribution companies should see a substantial number of savings accruing from these more efficient bulbs. The scheme plans for the discoms repaying EESL over a period of 5 to 8 years for the price of the bulbs, from the very savings that the bulbs have provided them. Because EESL is buying the bulbs in bulk, manufacturing companies can safely produce them at a scale in which the prices will come down.

Success in Puducherry

In Puducherry, where EESL carried out a 7.5 lakh LED bulb replacement project, that’s exactly what happened. Prices for a single bulb came down from Rs 400 to Rs 310. EESL then took the project to Andhra Pradesh, where last week it procured more than 20 lakh bulbs.

“Almost the entire lighting industry participated in the bid and the lowest quoted price was Rs 204 per LED bulb,” the power ministry said. “This is almost 35% less than the Puducherry LED price and about 50% below the price at the beginning of the year.”

Although this still makes them more expensive than CFLs, they have become much more competitive. More standardisation and labelling, which the BEE is promoting, could see LEDs become price-competitive enough to take the place of CFLs.

“The rapid price reduction as a result of aggregation of demand augurs well for promoting energy efficiency in lighting sector with the state of the art LED technology,” the ministry said.