The Japanese farmer philosopher Masanobu Fukuoka said, “There is no time in modern agriculture for a farmer to write poetry or compose a song.” For though life for the farmers of old was a perennial cycle of work, traditional agricultural life had set patterns of rest, festivals, ritual and – if one was so inclined – the time to write. Fukuoka believed that the farmer must write – poetry, songs and stories of the joys and sorrows of life. For who could be better equipped to write than the farmer? Who observes the change of seasons, the brightness of the stars, the formations of the clouds and the fragrance of rain in the air as astutely as the farmer? Who could fathom the moods and shades of mountain, sky, earth and rivers to create a masterpiece of art, if not a farmer? Who could speak of love more eloquently than a farmer, whose proximity to the elements of nature gave him an advantage – to equate his emotions to the changing seasons, the mystery of rain clouds, the flight of birds and the unfurling of a tender bud? Fukuoka once saw a mysterious phenomenon in his own fields: millions of spiders weaving silken webs on the rice stubble after the harvest. Seeing this, he wrote, “You understand that poets and artists will have to join the gathering.”

Over years of being in the company of farmers and food producers, I have been constantly surprised and moved by their sensitivity and deep understanding of nature and the ways of the world. Behind the wry humour lies a depth of knowledge and a pragmatic outlook towards life. Farming was no passive endeavour, but a craft that needed to be honed to perfection. Through the ages, books on agricultural practices were compiled by farmers and rishis, wise men from agrarian communities. The books were no boring tomes, but documents of wit and wisdom, with attention to beauty and detail. Man’s own weaknesses and frailties, his ego and vanities were mocked, a constant reminder that he was just a cog in the universal wheel, and of all he had to be thankful for. There is a song, a couplet, a fable or a quote for every occasion in agrarian life, and words on the seasons of farming, on how to observe the zodiac to plan agricultural activities on auspicious days or on studying the seasons to predict rain and winds, and astute advice about the environment. “Know that forests should not be felled, even in times of distress for when forest cultivation is done, it [the area] is entirely dependent on natural rainfall.” On farming and family matters, come these words of advice in an old farming almanac: “An unmatched pair of bullocks is as unproductive as a poorly matched couple in marriage, each straining in opposite directions, and no work gets done.”

Most agricultural traditions were passed down orally through the ages and farming communities have ingenious methods of transferring knowledge through storytelling, poetry, legend, folklore and music. The agrarian Khasi tribes have a vast repository of legends and folk tales called phawar, passed down generations in the oral tradition. They were related around the family hearth, often accompanied by a dui-tara, or sung while working in the rice fields. Myths and sacred stories are called khanatang, legends are khana pateng, folk tales are parom and stories of animals paju, while the riddle, an endearing Khasi feature, is called jingkyntip. As the British missionaries slowly eroded folk culture and branded their traditions as heathen practices, a few Khasi scholars tried to record the old folk tales, poetry and maxims which narrate the stories of nature and the mysteries of the universe. Like parables, the phawars form a structure of morality and society even today, reminding them of their traditions and culture, and of the perils of greed, foolishness, laziness and other human frailties. As the poet Rabon Singh Kharsuka advises sternly:

“Tend to your land, your flock

Work, manufacture with hands and skills

Make your own wealth, increase it

The mind becomes fertile and life prospers.”

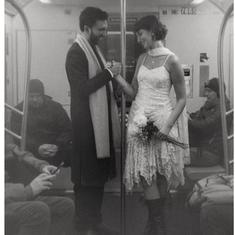

But there is clarity and purpose in the patterns of farming life: work, food, a song in your heart, and even time for a little romance. Life is often hard, an endless cycle of work that never ends, but as this exuberant rhyme expresses, he would not have it any other way.

“Where will you get a life like the farmer’s?

We have rice in the house and meat in the sheds;

My implements readied, I leave for work

Carrying my axe, spade, khoh and star;

No stumbling, sans worry, I leave free of care

Singing a ditty, whistling a song;

Clear is my head, my heart, my voice

As I hummed I spied two pretty girls;

They stopped and asked, where are you from?

From Riatsamthiah, I replied at once;

I noticed one wore a ryndia stem

And my heart overflowed with excitement.”

The fourteenth-century philosopher-poet Ghagh wrote eloquent poems about every aspect of farming life, which were passed on through generations of farmers in north India. With his wife Bhadari, he wrote pithy verses on a range of topics from farming advice to family matters – for in most agrarian communities the two are intrinsically connected. His poems, full of earthy wisdom and humour, were popular with the farmers and peasants of Punjab, Haryana and Uttar Pradesh, and a well-used copy of his book – Ghagh Bhadari Ki Kahaavatein – is found in many farmhouses even today.

In one of his whimsical poems he declares:

“Heaven would be a farm close to a village, with Ghagh the proud owner of four pairs of bulls for ploughing,

A milk cow, a duo of blood brothers as companions

And a wife who still gives her man a coy glance when she serves him a good meal—

A ladle full of arhar dal on fragrant freshly made rice,

Fresh butter, lemon slices and

A bowl of rich yogurt solid as a duck’s egg, topped with raw sugar.

Yes, that would be Ghagh’s Kailas, his heaven.”

Krishi Geetha (The Farmer’s Song) is a fascinating treatise from the ancient Malayalam Desam, modern-day Kerala, which then comprised the Chera kingdom and parts of the Chola kingdom. Written over a few centuries as a discourse between Parasuram, one of the ten incarnations of Vishnu, and the landowning Brahmins, the agricultural tome addresses the various aspects of agriculture in the form of verse. The author (or authors) of the book are unknown, but it can be deduced that he had a deep knowledge of agriculture, geography and politics, and may have been a farmer. As the farmer–poet travels to distant lands learning about new agricultural practices, he spreads this knowledge in the form of verse in a guidebook.

“In your territory known as Malayalam Desam,

Often it may be possible to grow some of the navadhanyas—

Wheat, rice, red gram, mung bean, chickpea, beans, sesame, black gram and horse gram.

However, navadhanyas are widely grown outside.

Listen, how wonderful are the sesame and other wild seeds.”

Excerpted with permission from Mother Earth, Sister Seed: Travels Through India’s Farmlands, Lathika Geoge, Penguin Random House.